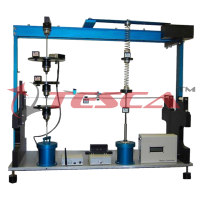

Cam Analysis Machine

Order Code: 32127

Category: Strength of Materials Lab

Features: Motorized unit Sturdy design Mobile, compact, comprehensive, sturdy design Fully instrumentation for experimentation of Cam Analysis Machine study User-friendly operation Tesca Cam Analys...

SPECIFICATION

Features:

- Motorized unit

- Sturdy design

- Mobile, compact, comprehensive, sturdy design

- Fully instrumentation for experimentation of Cam Analysis Machine study

- User-friendly operation

Tesca Cam Analysis Machine is a motorized unit consisting of a camshaft driven by a D.C. Motor. The shaft runs in a double bearing. The free end of the camshaft has a facility to mount the cam easily.

The follower is properly guided in gunmetal bushes and the type of follower can be changed according to the cam under test. A graduated circular protractor is fitted co-axial with the shaft. And a Dial Gauge fitted on the follower shaft is used to note the follower displacement for the angle of cam rotation. A spring is used to provide controlling force to the follower system. Weights on the follower shaft can be adjusted as per the requirement. A speed controller is provided to regulate the speed. The apparatus is very useful for testing the cam performance or jump phenomenon during operation. It is useful for testing various cam & follower pairs.

System Components:

- Cams

- Tangent, Eccentric, circular Arc.

- Followers

- Roller, knife-edge, Mushroom

- Compression spring.

- Weights - 1 kg, 500 gm, 100gm

- D.C. motor: ¼ HP. 0-1500 rev/min.

- Speed control unit.

Experiments Capabilities:

- For the combinations of cams and followers provided, the following tests can be conducted Plotting and analysis of the X-0 curve

- The velocities and accelerations of the follower may be derived and hence inertia forces plotted over the whole lift period. The condition of follower bounce can clearly be known by carrying out theoretical calculations and graphs from the X – 0 curves.

- Follower bounce can be observed by using a stroboscope.

- To study the effect of follower weights (W) on the speed of bounce.

- To study the effect of initial spring compression on the speed of bounce

- A test can be repeated by changing parameters like various compression springs, follower weights, and Cam speeds.

Required Services:

- 230V A/C, 50 Hz, Single phase mains supply.

- A bench area of approx. 700 x 610 mm

91-9829132777

91-9829132777